Colorful Coating Agents

1. Aqueous film-coating of high quality

2. Ready-to-use

3. For instant release

4. Easy to handle

5. Good film adhesion

6. Good logo definition

Colorful coating agents

The current solutions in tablet coating face challenges in meeting the increasing consumer demand for natural ingredients while adhering to stricter regulations, particularly in Europe. Our Naturally Color coating system addresses these issues by offering tablet coating agents formulated to provide vibrant, stable, and natural colors. These formulations are designed to comply with regulations that restrict the use of aluminum and pure dyes, ensuring both regulatory compliance and consumer satisfaction with naturalness.

Product introduction

Our Naturally Color coating system has been specifically developed to meet the demand for vibrant, natural colors in food supplements, without compromising on coating performance or color stability. Here are the key attributes of our system:

✮ Aluminum-free: Our coatings do not contain aluminum.

✮ TiO2-free: They are free from titanium dioxide.

✮ Artificial and Azo dye-free: Our formulations exclude artificial and azo dyes.

✮ GMO-free: We guarantee that our coatings are free from genetically modified organisms.

Our Naturally Color coating system exclusively uses coloring foodstuffs derived from fruits, vegetables, edible plants, and algae. Importantly, these natural sources do not bear any E numbers, aligning perfectly with clean-label preferences and consumer-friendly supplement requirements.

In summary, our Naturally Color coating system offers a superior solution for supplements, ensuring natural and vibrant colors while meeting strict regulatory standards and consumer expectations for clean-label products.

Application of Colorful Coating Agent

Our colorful coating agent is fully compliant with EU food supplements regulations and can be used for:

Food supplements

Confectionery

Some of the references are with US food supplements regulations.

Technology of film coating

1. Sugar coating

It is a multi-step process.

➢ In suitable sugar–coating equipment, the tablet cores are successively treated with aqueous sucrose solutions.

➢ Water evaporates from the syrup leaving thick film.

➢ Sugar coats are often shiny and highly coloured.

2. Film coating

It involves spraying a solution of polymer along with the plasticizer and pigments on a rotated, mixed tablet bed forms a thin uniform film on the tablet surface.

In the wet state, the polymer is present as a no. of discrete particles, and these have to come together in close contact, deform, coalesce and ultimately fuse together to form a discrete film. During processing, the substrate surface will be wetted with the diluted dispersion. Under the prevailing processing conditions, water will be lost as water vapour and the polymer particles will increase in proximity to each other, a process which is greatly assisted by the capillary action of the film of water surrounding the particles. Complete coalescence occurs when the adjacent particles are able to mutually diffuse into one another.

3. Enteric coating

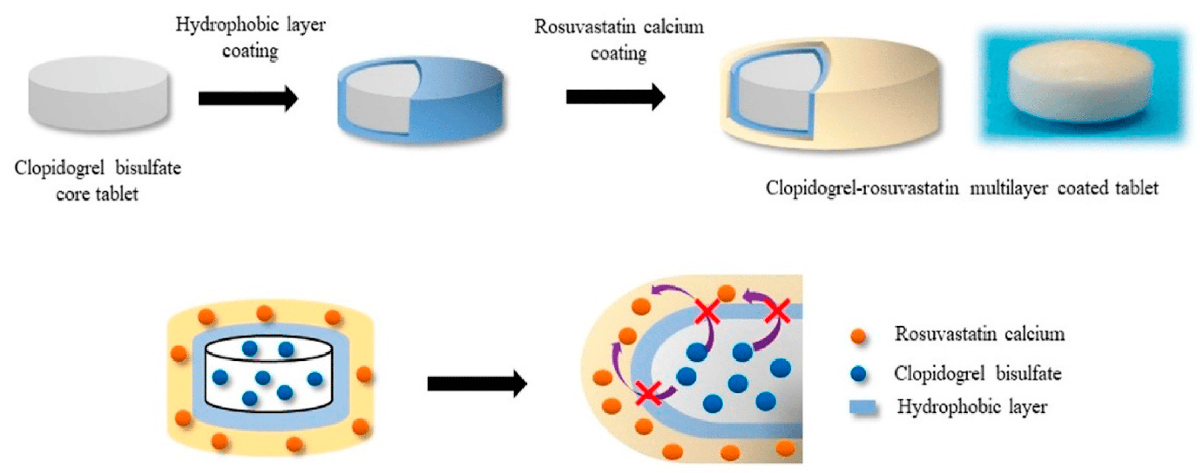

The technique involved in enteric coating is protection of the tablet core from disintegration in the acidic environment of the stomach by employing pH sensitive polymer, which swell or solubilize in response to an increase in pH to release the drug.

4. Press coating

It involves the compaction of granular materials around preformed tablet core using specially designed tablet equipment. Compression coating is a dry process.

It is mainly used to separate chemically incompatible materials.

Workshops

Introducing advanced Japanese technology, our production equipment and processes feature fully automated central control operations. From raw material feeding to final products, automated controls are implemented to ensure consistent product quality.

After-sales service

Our engineers offer round-the-clock online support, available 24/7, to resolve any technical issues related to tablet coating promptly. With robust research and development capabilities, we also ensure efficient ODM production.