Moisture Barrier Film Coating

1. Precision production line of German origin.

2. Fully automatic unmanned production line.

3. Exquisite craftsmanship from Japan.

4. ODM, Address diverse requirements.

5. Robust research and development capabilities.

6. GMP standard workshops.

Moisture barrier film coating

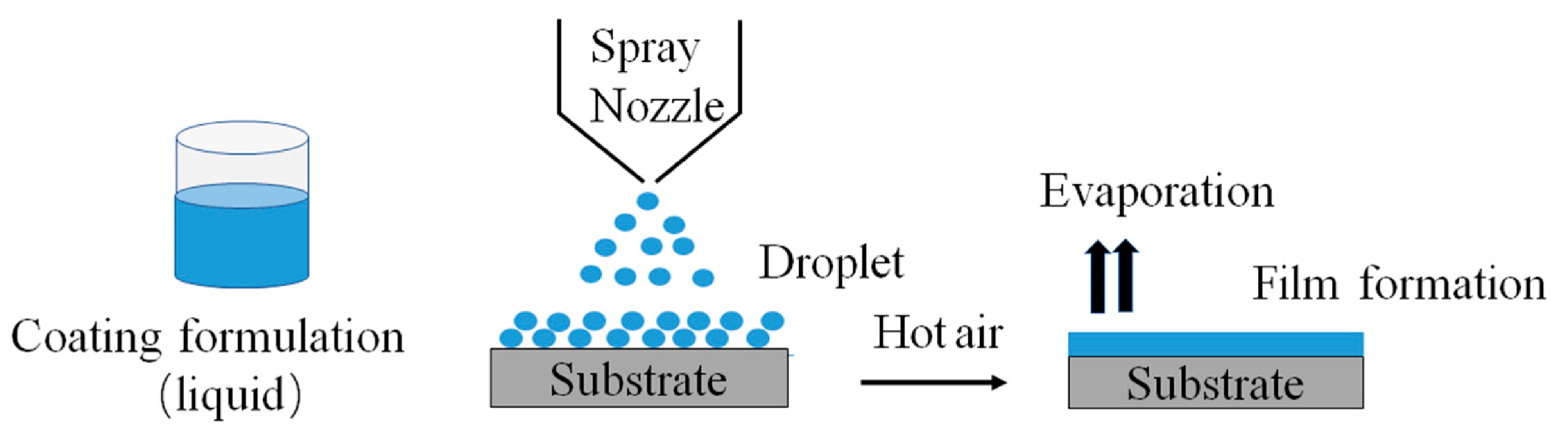

Moisture barrier film coating is one of the most appropriate and effective approaches to protect the active pharmaceutical ingredients (API) from hydrolytic degradation during the manufacturing process and storage. Coating formulation design and process control are the two most commonly used strategies to reduce water vapor permeability to achieve the moisture barrier function. The principles of formulation development include designing a coating formulation with non-hygroscopic/low water activity excipients, and formulating the film-forming polymers with the least amount of inherent moisture. The coating process involves spraying organic or aqueous coating solutions made of natural or synthetic polymers onto the surface of the dosage cores in a drum or a fluid bed coater.

Product introduction

Moisture barrier film coating is indeed a highly effective method to safeguard active pharmaceutical ingredients (APIs) from hydrolytic degradation throughout manufacturing and storage processes. There are two primary strategies employed to achieve effective moisture barrier properties:

★ Coating Formulation Design: This strategy focuses on the composition of the coating material itself. Formulations are carefully designed to include ingredients that minimize water vapor permeability. For instance, polymers with inherently low moisture absorption properties, such as ethylcellulose or certain acrylic polymers, are often chosen. These polymers form a dense, impermeable layer when applied as a coating, thereby reducing the ingress of moisture into the pharmaceutical core.

★ Process Control: The second strategy involves precise control over the coating application process. Parameters such as coating thickness, drying conditions, and curing times are meticulously managed to ensure uniformity and integrity of the moisture barrier coating. Variations in these parameters can significantly impact the effectiveness of the barrier against water vapor ingress.

Together, these strategies—coating formulation design and process control—work synergistically to achieve optimal moisture barrier properties in pharmaceutical products. By implementing these approaches, manufacturers can enhance the stability and shelf life of APIs, ensuring they maintain their efficacy and safety throughout their intended lifespan.

Workshops

Introducing advanced Japanese technology, our production equipment and processes feature fully automated central control operations. From raw material feeding to final products, automated controls are implemented to ensure consistent product quality.

After-sales service

Our engineers offer round-the-clock online support, available 24/7, to resolve any technical issues related to tablet coating promptly. With robust research and development capabilities, we also ensure efficient ODM production.