polymers used in tablet coating

1. Safe, Non-toxic, Every ingredient under toxicological studies.

2. ODM, Address diverse requirements.

3. Robust research and development capabilities.

4. A homogeneous ready-mix film coating system for tablets, comprising essential ingredients like film-forming polymers, plasticizers, pigments, opacifiers, and additional additives.

Polymers used in tablet coating

Tablet coating involves applying a thin layer of a coating material to the surface of a tablet. This process serves several purposes, such as protecting the tablet's core, controlling the release of the drug, and improving the tablet's aesthetic qualities. Coating can be performed through various methods, each chosen based on the desired outcome and the specific properties of the active pharmaceutical ingredient (API) and excipients used

Pharmaceutical Application

1. Protection: Coating helps protect the active pharmaceutical ingredient (API) from environmental factors such as moisture, light, and oxygen, which can degrade the drug's effectiveness.

2. Controlled Release: Coatings can be designed to modify the release profile of the drug. This allows for extended or delayed release of the medication, improving therapeutic outcomes and patient compliance.

3. Taste Masking: Many APIs have unpleasant tastes. Coating can mask these flavors, making the tablet more palatable, especially for pediatric and geriatric populations.

4. Improved Appearance: Aesthetic aspects are important for consumer acceptance. Coatings can enhance the color and gloss of tablets, making them visually appealing and easier to identify.

5. Enhanced Handling: Coated tablets often have improved mechanical properties, which reduce the risk of abrasion and breakage during handling and transport.

6. Identification: Color coding and other visual markers can be integrated into the coating to help identify the medication easily, reducing the risk of medication errors.

Workshops

Introducing advanced Japanese technology, our production equipment and processes feature fully automated central control operations. From raw material feeding to final products, automated controls are implemented to ensure consistent product quality.

After-sales service

Our engineers offer round-the-clock online support, available 24/7, to resolve any technical issues related to tablet coating promptly. With robust research and development capabilities, we also ensure efficient ODM production.

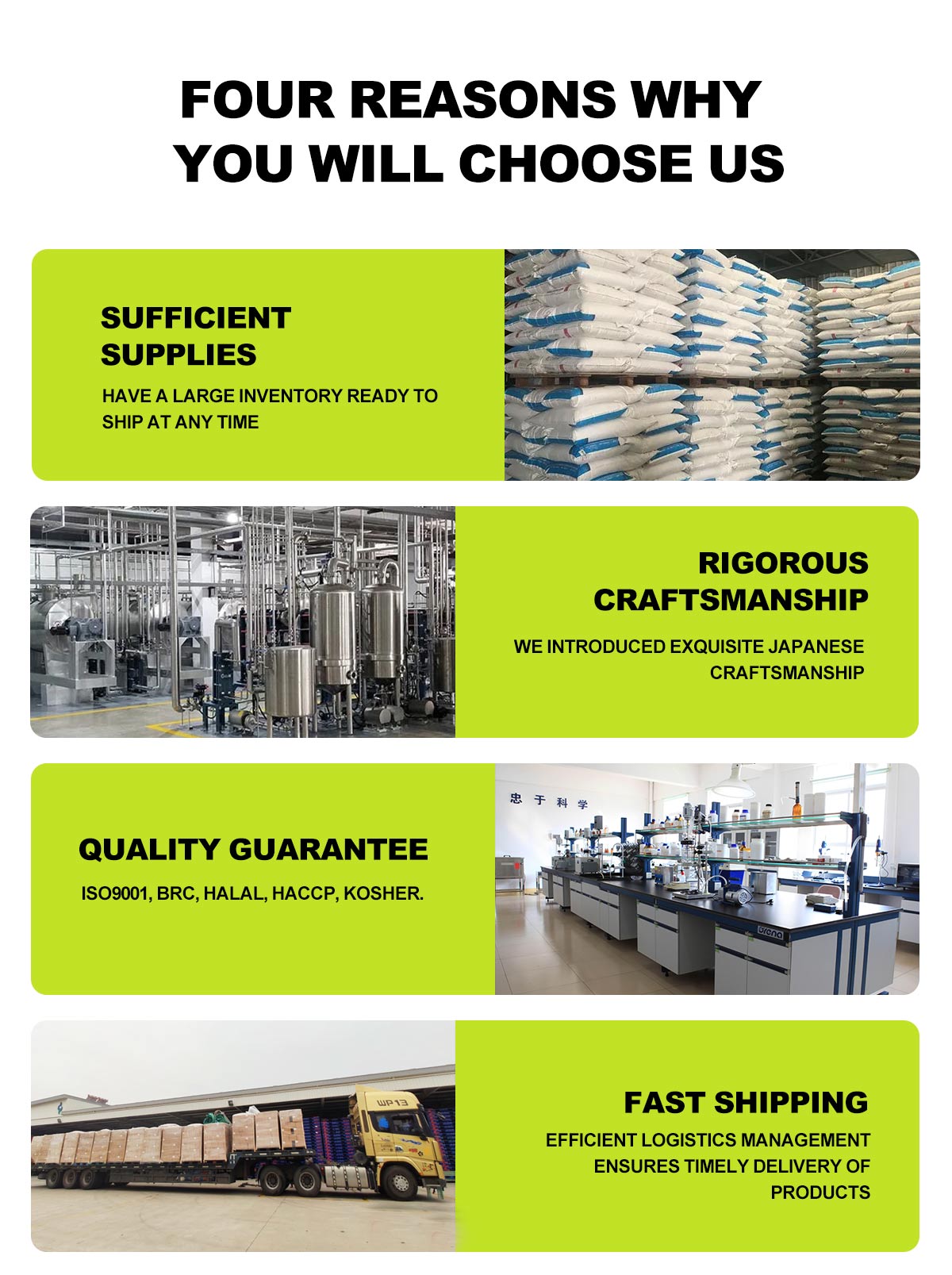

The reasons why you will choose us