tablet film coating materials

1. Safe, Non-toxic, Every ingredient under toxicological studies.

2. ODM, Address diverse requirements.

3. Robust research and development capabilities.

4. A homogeneous ready-mix film coating system for tablets, comprising essential ingredients like film-forming polymers, plasticizers, pigments, opacifiers, and additional additives.

5. Approved premises by the FDA, supported by Current Good Manufacturing Practices (CGMP) and Quality Systems, ensure consistent high-quality products.

Film Coating premix

Our premium Film Coating Agent is designed to enhance the appearance, stability, and functionality of pharmaceutical tablets. It forms a thin, uniform layer on the tablet surface, offering numerous benefits that improve both the manufacturing process and the patient experience.

Product introduction

Aesthetic Enhancement:

Provides tablets with a smooth, glossy finish for a professional appearance.

Available in various colors to support product differentiation and branding.

Taste Masking:

Effectively masks the taste and odor of active pharmaceutical ingredients (APIs), improving patient compliance and making tablets more palatable.

Moisture Barrier:

Acts as a protective layer, preventing moisture penetration and enhancing the stability and shelf life of sensitive APIs.

Controlled Release:

Can be customized for immediate or modified release (extended or delayed), ensuring the desired therapeutic effect over time.

Improved Swallowability:

The coating provides a smoother surface, reducing friction and making the tablets easier to swallow for patients.

Compatibility with Various Tablet Cores:

Formulated to be compatible with a wide range of tablet cores, including those containing sensitive or hydrophilic ingredients.

Pharmaceutical Application of Film Coating

Pharmaceutical Tablets: Ideal for prescription and over-the-counter (OTC) medications requiring aesthetic, functional, or protective coatings.

Nutraceuticals & Dietary Supplements: Enhances the visual appeal and stability of supplements, ensuring consumer satisfaction.

Workshops

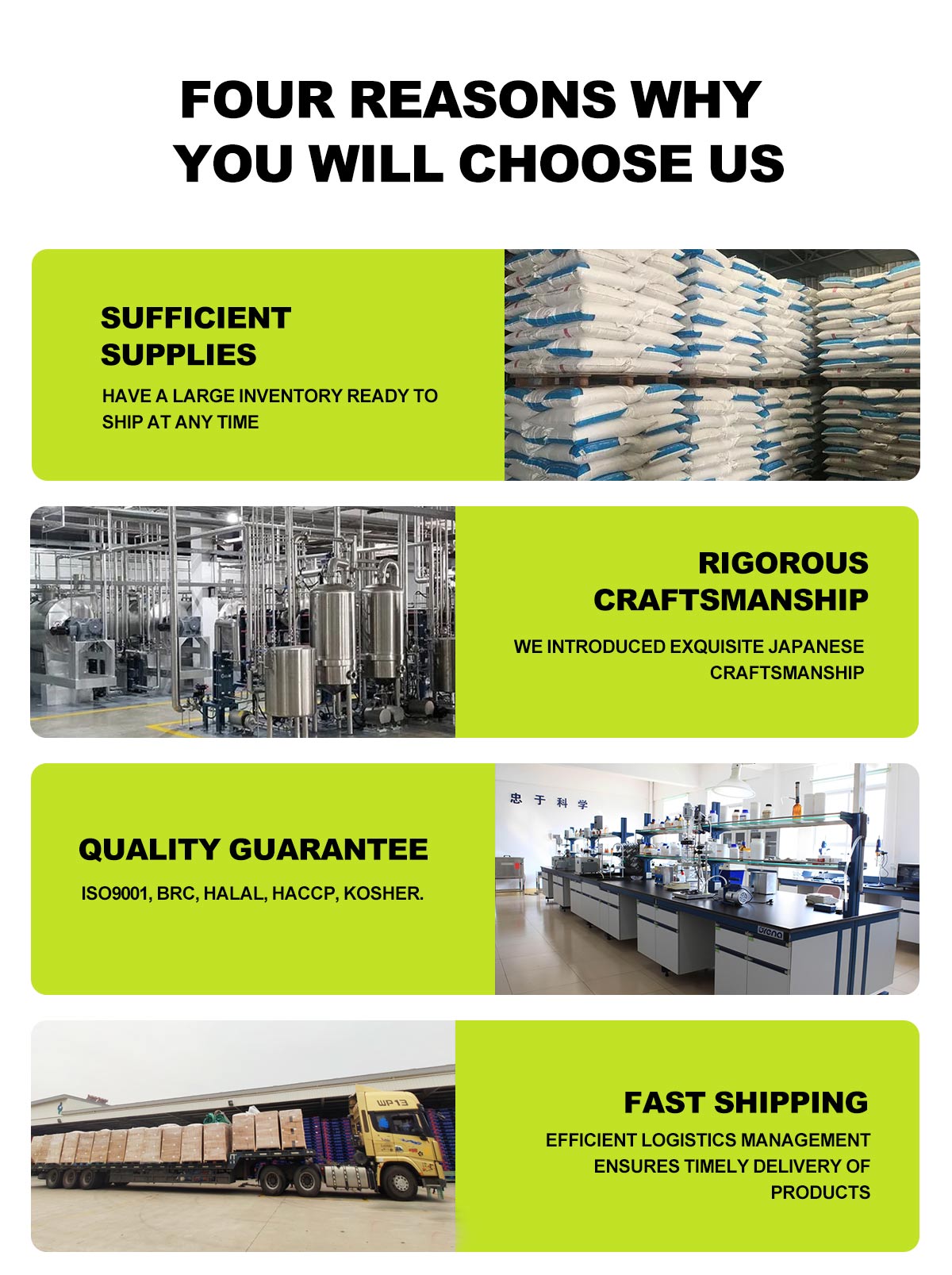

Introducing advanced Japanese technology, our production equipment and processes feature fully automated central control operations. From raw material feeding to final products, automated controls are implemented to ensure consistent product quality.

After-sales service

Our engineers offer round-the-clock online support, available 24/7, to resolve any technical issues related to tablet coating promptly. With robust research and development capabilities, we also ensure efficient ODM production.

The reasons why you will choose us