Magnesium Stearate Lubricant

1. Precision production line of German origin.

2. Exquisite craftsmanship from Japan.

3. Address diverse requirements.

4. Color loose powder, feel creamy, insoluble in water, ethanol and ether, soluble in hot water, ether, case acid decomposition of stearic acid and the corresponding magnesium salt.

WhatsApp: +86 13405443339

Enterprise e-mail: info@sdshinehealth.com

Magnesium stearate is a white substance that has two equivalents of stearate and one magnesium cation. It is safe for human consumption. It is often used as a filling agent in the manufacture of supplement capsules. This substance has lubricating properties and prevents ingredients from sticking to manufacturing equipment during the compression of chemical powders into capsules or tablets. Most pharmaceutical formulations include a certain amount of lubricant to improve their flowability and prevent their adhesion to the surfaces of processing equipment.

Advantages

Magnesium stearate is preferred as an external dry lubricant to reduce granule adhesion, or sticking, to tablet press machine parts including the scraper blade, tooling punches, and hopper powder feeder system. This anti-sticking function also reduces die-wall friction which is often the root cause of higher tablet ejection forces. When added to cohesive dry solid formulations, magnesium stearate is applicable as a glidant, or a flow aid. It works by reducing inter-particle friction between solid particles that would otherwise adhere to one another and slow down the product’s flow rate. In the dry granulation process, Magnesium stearate functions as a dry lubricant to improve powder feeding into roller compactors.

Product Parameter

Product name | Magnesium Stearate |

CAS No. | 557-04-0 |

Purity | 99% |

Type | Adsorbent |

Classification | Chemical Auxiliary Agent |

Other Names | Magnesium Stearate |

MF | C36H70MgO4 |

Model Number | K |

Packaging Details | 1: 15 Kg/ bag |

Place of Origin | Shandong, China |

EINECS No. | 209-150-3 |

Appearance | A white, very fine, light powder |

Assay | The content of Mg: 4.0~5.0% |

Loss on drying | ≤5.0% |

Free Acid | ≤1.0% |

Melting point | 110~160℃ |

Particle size (through 325mesh) | ≥99% |

Usage | Coating Auxiliary Agents, Electronics Chemicals, Leather Auxiliary Agents, Paper Chemicals, Petroleum Additives, Plastic Auxiliary Agents, Rubber Auxiliary Agents, Textile Auxiliary Agents, Water Treatment Chemicals |

Conclusion | The results conforms with Enterprise standards |

Application

Magnesium stearate is often used as an anti-adherent in the manufacture of medical tablets, capsules and powdersFor powder cosmetics ingredients, can improve adhesion and lubricity. In the creation of pressed candies, magnesium stearate acts as a release agent and it is used to bind sugar in hard candies such as mints.

High-Quality Origin

Situated in prime agricultural regions, our production benefits from superior cultivation environments, combining mechanization and manual expertise to ensure the harvesting of the freshest raw materials.

Production Process

Our production process integrates advanced, fully automated central control systems. From raw material input to final product packaging, every stage undergoes automated precision control, guaranteeing consistent product quality. Key steps include crushing, extraction, filtration, concentration, purification, drying, grinding, testing, meticulous packaging, and efficient transportation.

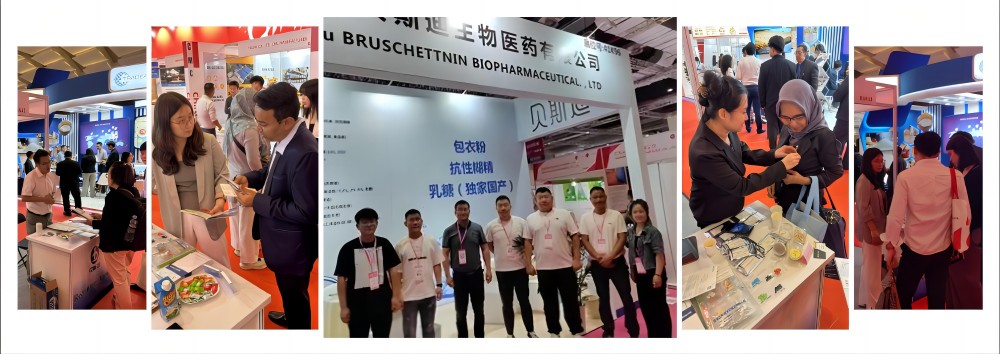

Customer Approval

We have garnered widespread customer acclaim over the years by consistently delivering products of exceptional quality. Our commitment to customer satisfaction is reflected in the positive feedback and trust we receive from our clients.

After-Sales Service

Complementing our high-quality products is our comprehensive after-sales service. We prioritize customer support, ensuring prompt assistance and solutions to meet our clients' needs throughout their product usage experience.