Premium Yellow Dextrin for Food Applications

1. Precision production line of German origin.

2. Exquisite craftsmanship from Japan.

3. Address diverse requirements.

4 Yellow dextrin stands out for its ease of use, stability across a range of processing conditions, and its ability to enhance texture and stability in food applications without compromising on sensory attributes.

Gelatin, colorless to pale yellow solid, in powder, flake or block. Shiny, odorless, tasteless. It is insoluble in water, but when immersed in water, it can absorb 5 to 10 times of water and swell and soften. If heated, it will dissolve into a colloid, and it will become a gel when cooled to below 35 to 40 °C; if the aqueous solution is boiled for a long time, Changes in properties due to decomposition, no gel formation after cooling. In food, it can be used as gelling agent.

Advantages

Yellow dextrin, characterized by its pale yellow color and availability in powder form, offers several distinct advantages in various applications. Primarily used as a gelling agent in food production, yellow dextrin exhibits excellent solubility in water, facilitating its incorporation into formulations without altering the product's color or flavor profile. Unlike gelatin, which requires specific temperature conditions to form a gel and is susceptible to decomposition upon prolonged heating, yellow dextrin remains stable under varying processing conditions.

Furthermore, yellow dextrin enhances the texture of food products by providing a smooth and consistent mouthfeel. Its ability to form stable gels at moderate temperatures ensures uniformity in food matrices without the risk of gel breakdown upon cooling. This property makes it ideal for applications where a stable gel structure is desired, such as in confectionery, bakery fillings, and dairy desserts.

Moreover, yellow dextrin's odorless and tasteless nature ensures that it does not impart any unwanted flavors to the final product, thereby preserving the sensory characteristics of foods. Its versatility extends beyond gelling; yellow dextrin also acts as a binder and stabilizer in various food formulations, contributing to the overall quality and shelf stability of processed foods.

In summary, yellow dextrin stands out for its ease of use, stability across a range of processing conditions, and its ability to enhance texture and stability in food applications without compromising on sensory attributes. These qualities make it a preferred choice among food manufacturers seeking reliable functional ingredients for their formulations.

Product Parameter

Appearance | Light yellow powder |

Odor | No-mildew |

Crude Protein (dry basis) | 26% max |

60% | |

Moisture | 10% max |

Ash Content | 5.0% max |

Fat Content | 1.0% max |

Particle Size(through 100 mesh)% | 90.0% min |

Absorption Capacity | Fiber: Water=1:8 |

Total plate count(cfu/g) | <30,000 |

E Coli.(cfu/100g) | Negative |

Salmonella (cfu/g) | Negative |

Application | Ketchup, meat products, quick-frozen products, seasonings, bakery, health products,also can be used into fat-free food, low-fat&low sugar and high fiber food. |

Application

Maltodextrin is a crucial ingredient in a variety of high-quality food products renowned for their nutritional value and culinary versatility. It is extensively employed in dietetic and baby foods, where its mild flavor and easy digestibility contribute to its suitability for sensitive diets. As a spray-drying carrier, maltodextrin enhances the solubility and stability of powdered formulations, ensuring consistent texture and flavor release in products such as soup and sauce mixes, as well as mayonnaise and dressings.

In the realm of snack foods, maltodextrin plays a pivotal role in the production of extruded snacks, offering texture enhancement and crispiness. Its use extends to coffee mates, where it serves as a bulking agent and improves mouthfeel without altering the coffee's taste profile. Maltodextrin also finds application in frozen foods, aiding in texture modification and preventing ice crystal formation, thereby preserving product quality.

High-Quality Origin

Situated in prime agricultural regions, our production benefits from superior cultivation environments, combining mechanization and manual expertise to ensure the harvesting of the freshest raw materials.

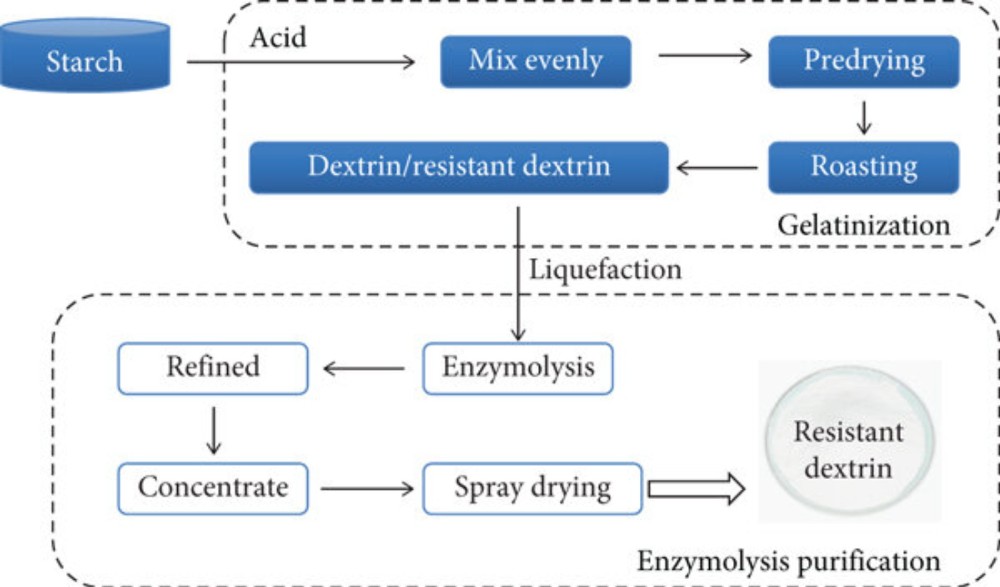

Production Process

Our production process integrates advanced, fully automated central control systems. From raw material input to final product packaging, every stage undergoes automated precision control, guaranteeing consistent product quality. Key steps include crushing, extraction, filtration, concentration, purification, drying, grinding, testing, meticulous packaging, and efficient transportation.

Customer Approval

We have garnered widespread customer acclaim over the years by consistently delivering products of exceptional quality. Our commitment to customer satisfaction is reflected in the positive feedback and trust we receive from our clients.

After-Sales Service

Complementing our high-quality products is our comprehensive after-sales service. We prioritize customer support, ensuring prompt assistance and solutions to meet our clients' needs throughout their product usage experience.